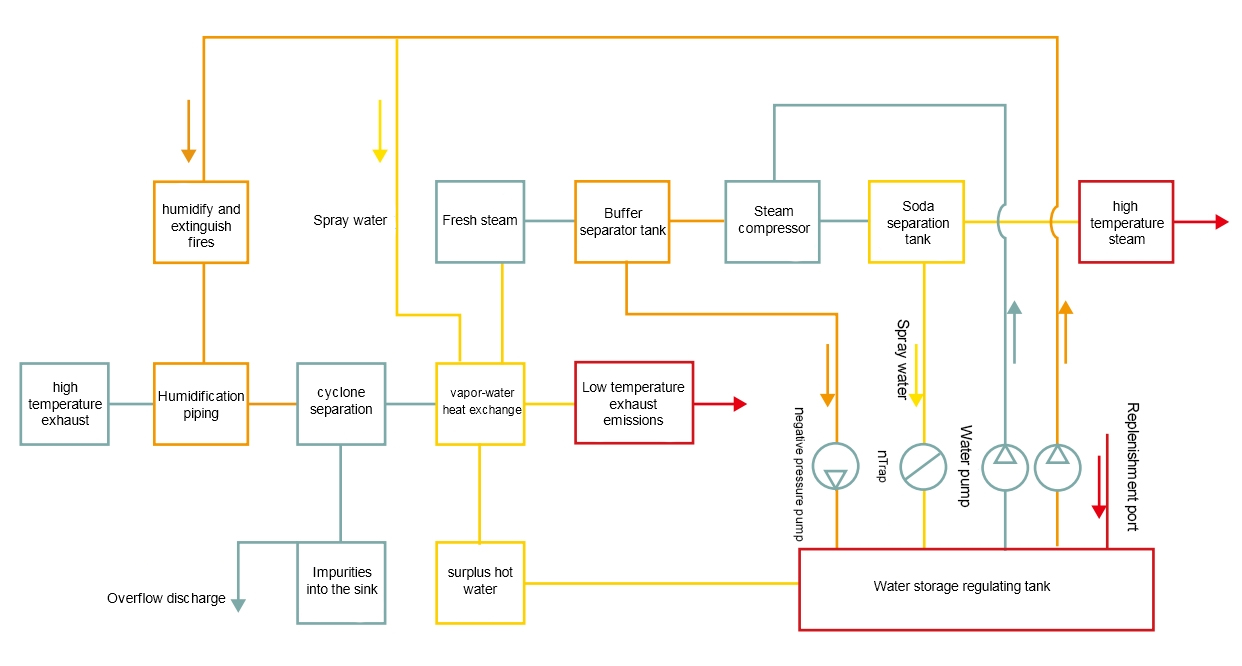

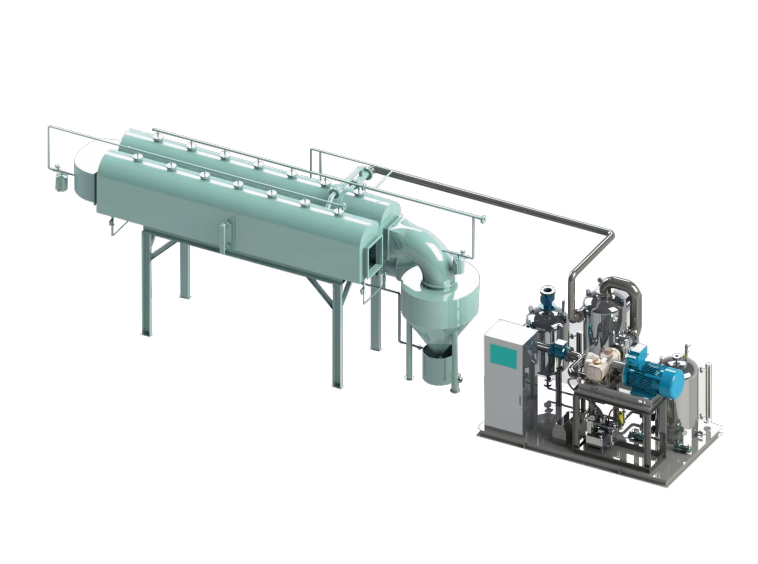

Working Principle

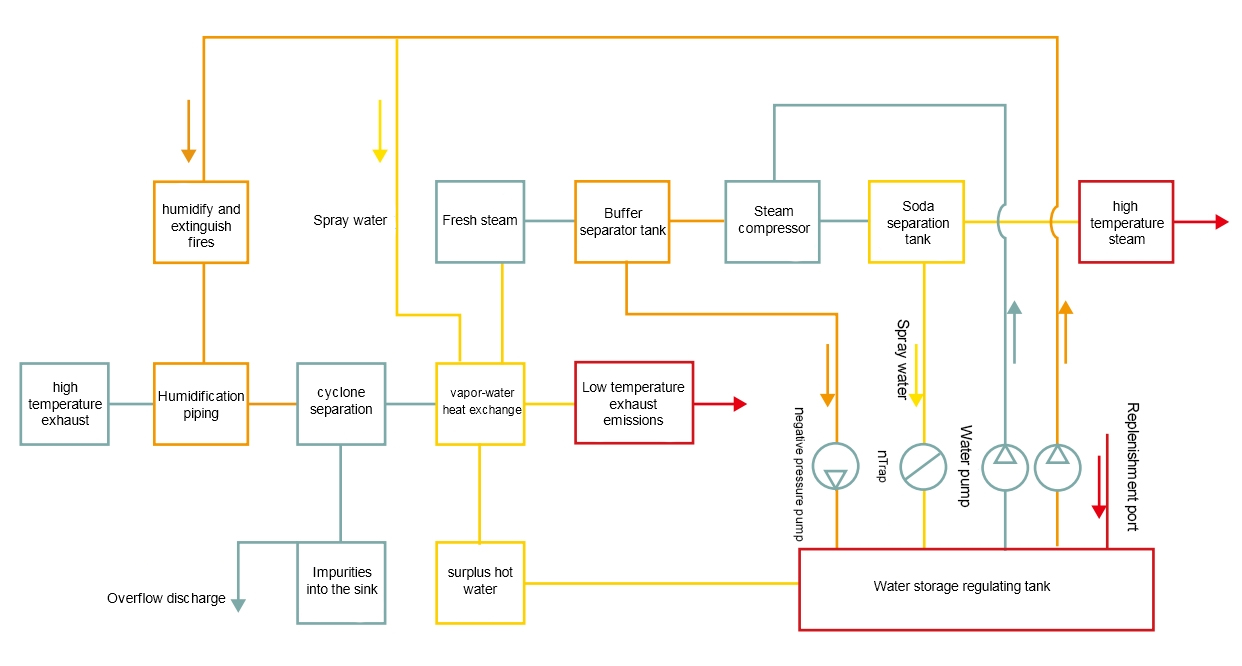

This unit humidifies the high-temperature exhaust gas, separates oil dirt and impurities, and then enters the heat transfer tube process. After two-pass exchanges, the high-temperature spray water is converted into steam. It is pressurized and heated by the compressor to produce 3-4 kilograms of high-temperature steam for direct supply to the user. The heated hot water is sent to the air duct machine to provide a heat source for shaping the air inlet and save a lot of steam. This unit is equipped with a fire prevention nozzle and a heat exchange tube cleaning nozzle, which has the functions of automatic fire extinguishing and regular automatic cleaning of the pipe wall.

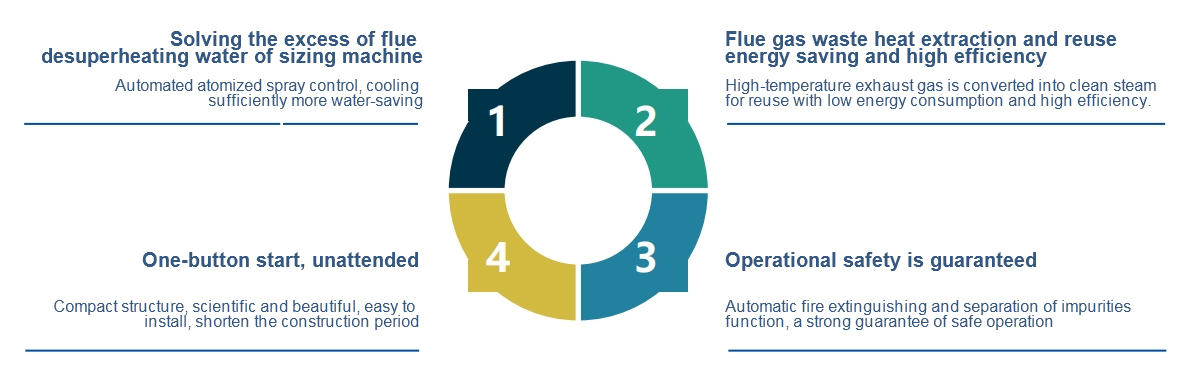

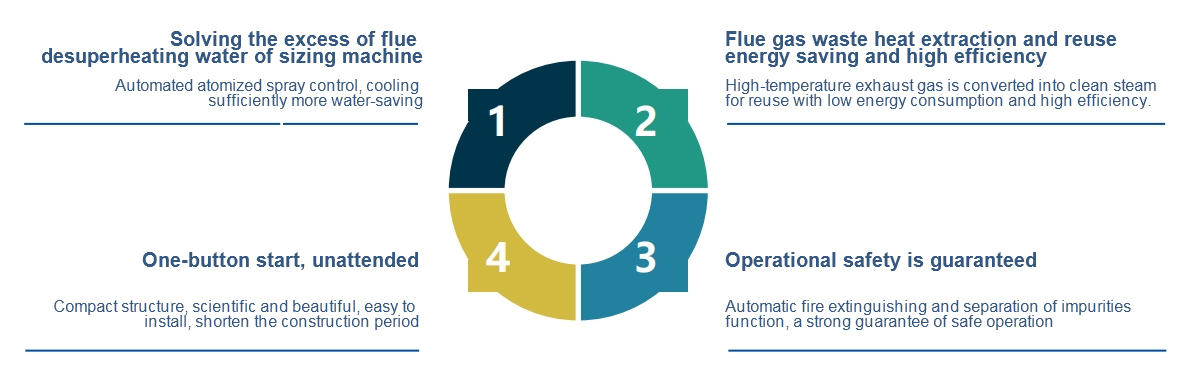

Product Features

Unit Parameters

|

Unit type/test parameters

|

High temperature exhaust gas temperature ℃

|

Conversion steam temperature ℃

|

Conversion steam pressure Mpa

|

Electricity consumption of tons of steam kw.h/ton

|

Steam quality tons/h

|

|

GQZQ-1

|

140-190℃

|

140-152℃

|

0.3Mpa-0.4Mpa

|

140-160

|

1

|

|

GQZQ-1.5

|

140-190℃

|

140-152℃

|

0.3Mpa-0.4Mpa

|

140-160

|

1.5

|

|

GQZQ-2

|

140-190℃

|

140-152℃

|

0.3Mpa-0.4Mpa

|

140-160

|

2

|

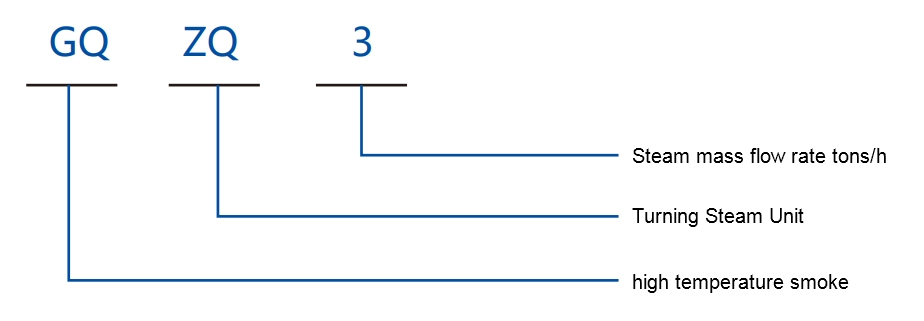

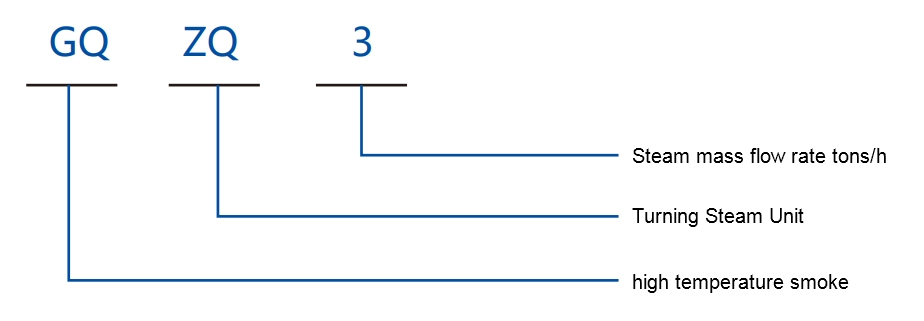

Product Model Description

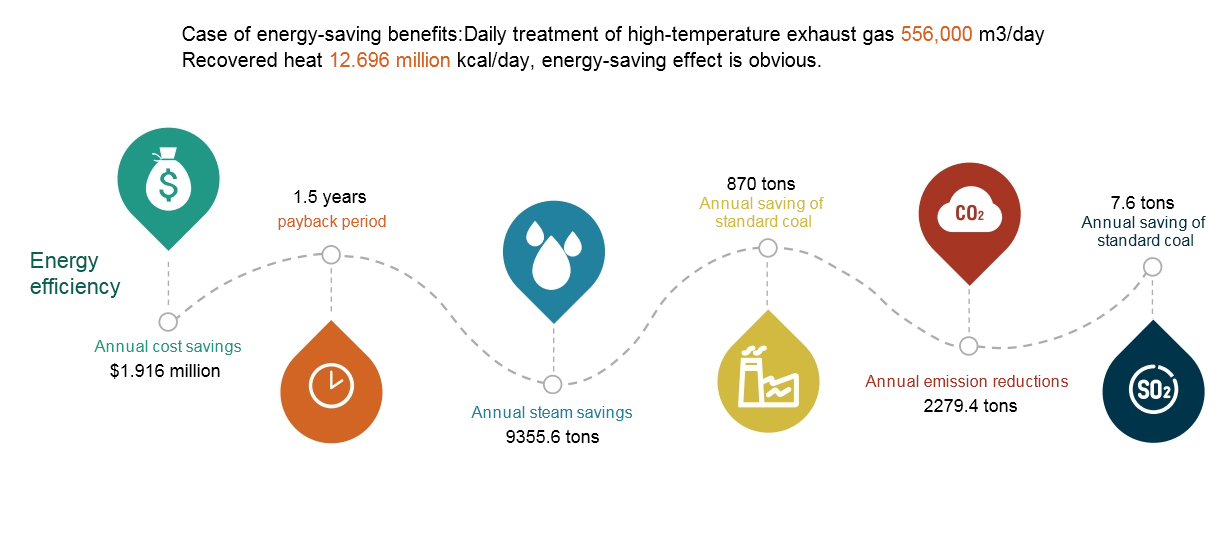

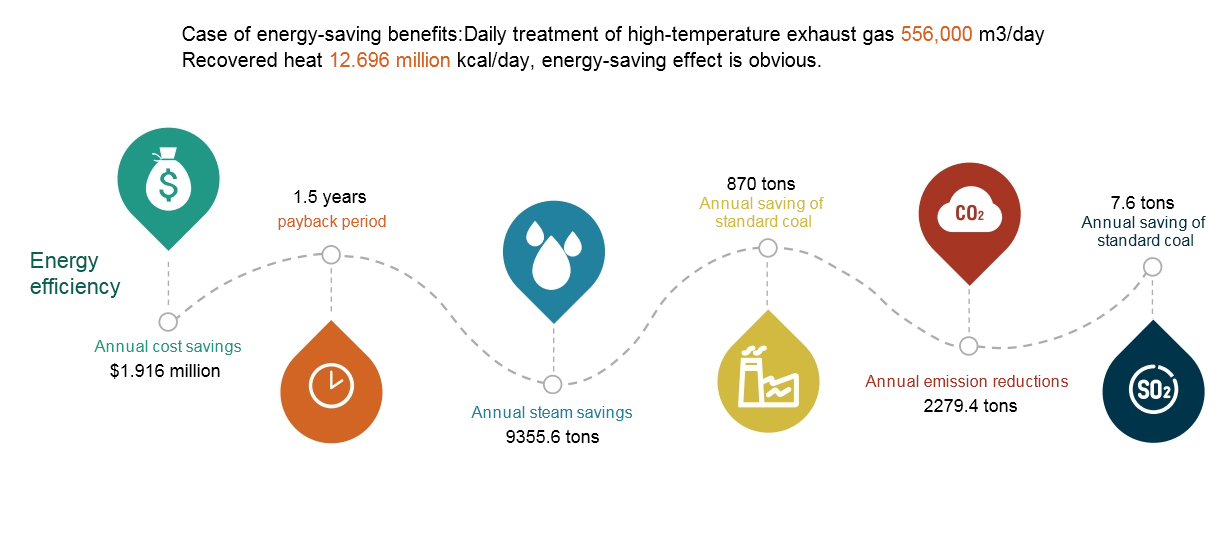

Energy efficiency gains

System Process

Areas Of Application

鲁公网安备37100202000865号

鲁公网安备37100202000865号