Working Principle

MVR evaporation unit is evaporation concentration equipment that uses a steam mechanical compressor to compress and heat the secondary vapor generated by the evaporator into heated steam and recycle it.

The process principle is to use the secondary steam generated in the evaporator, compress it by the compressor to increase the pressure and temperature, increase the heat enthalpy, and then deliver it to the heating chamber of the evaporator for use as heating steam to maintain the boiling state of the material liquid, thereby replacing steam once. In this way, the original secondary steam is fully utilized, latent heat is recovered, and thermal efficiency is improved. The energy consumption of MVR is equivalent to 1/3 of the steam multi-effect evaporation process, which reduces production costs and carbon emissions.

Different types of steam compressors are used according to different user needs, such as magnetic levitation steam compressors, high-speed directly driven steam compressors, gearbox steam compressors, etc. The MVR evaporation concentration (crystallization) unit has a comprehensive energy saving of more than 66% compared with the steam multi-effect evaporation process, and the noise can be reduced by more than 20 dB.

Product Features

Unit Parameters

|

evapotranspiration(T/H)

|

Heat exchanger form

|

Concentration/crystallization

|

Configuration version

|

Product Model

|

|

1ton (loanword)

|

Plate/Shell & Tube

|

Concentration/crystallization

|

standard configuration

|

CMVR-1

|

|

2ton (loanword)

|

Plate/Shell & Tube

|

Concentration/crystallization

|

standard configuration

|

CMVR-2

|

|

3ton (loanword)

|

Plate/Shell & Tube

|

Concentration/crystallization

|

standard configuration

|

CMVR-3

|

|

5ton (loanword)

|

Plate/Shell & Tube

|

Concentration/crystallization

|

standard configuration

|

CMVR-5

|

|

7ton (loanword)

|

Plate/Shell & Tube

|

Concentration/crystallization

|

standard configuration

|

CMVR-7

|

|

9ton (loanword)

|

Plate/Shell & Tube

|

Concentration/crystallization

|

standard configuration

|

CMVR-9

|

|

Xton (loanword)

|

Plate/Shell & Tube

|

Concentration/crystallization

|

standard configuration

|

CMVR-X

|

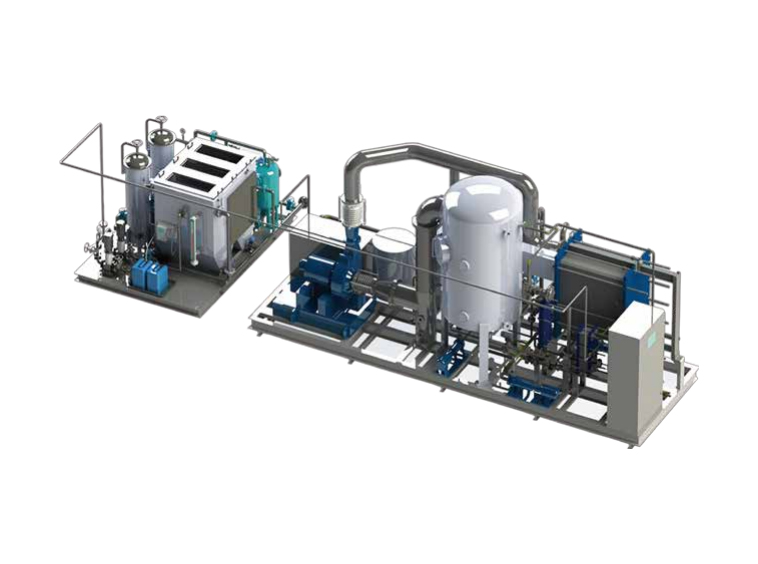

System Components

Energy cost per ton for multiple evaporators

|

form

|

work unit (one's workplace)

|

Evaporation of capacity expansion

|

Triple effect evaporation

|

Shandong Shuanghe MVR evaporation

|

|

Hourly power consumption

|

KWH/hourly

|

15

|

15

|

39

|

|

Hourly steam consumption

|

tons/hour

|

0.6

|

0.38

|

Only a small amount is

required for startup

|

|

Running cost per hour

|

Yuan/hour

|

155.3

|

102.5

|

29.3

|

|

Total annual running costs

|

ten thousand dollars

|

111.8

|

73.8

|

21.1

|

Note: The electricity fee is 0.75 yuan/kwh, the steam cost is 240 yuan/ton, and the annual operating time is 7200h.

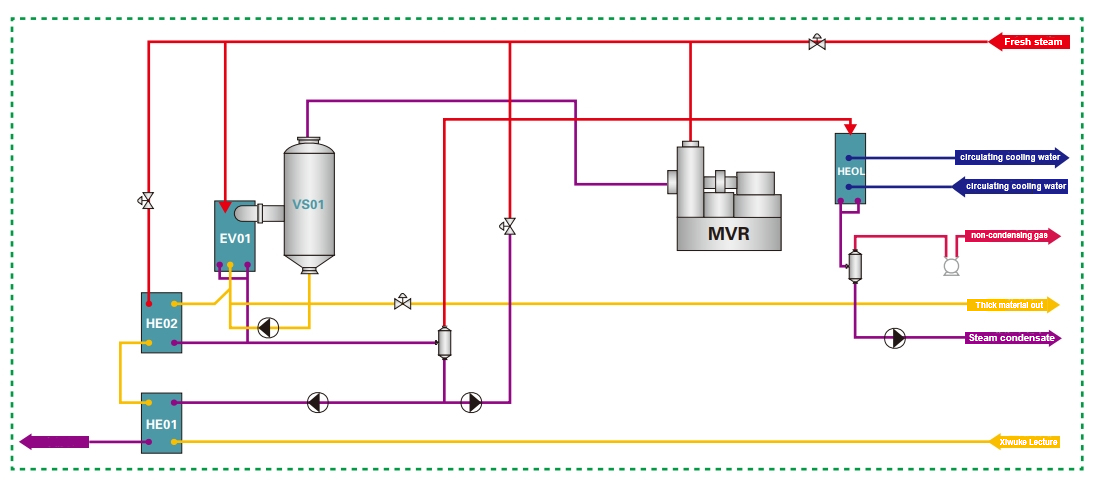

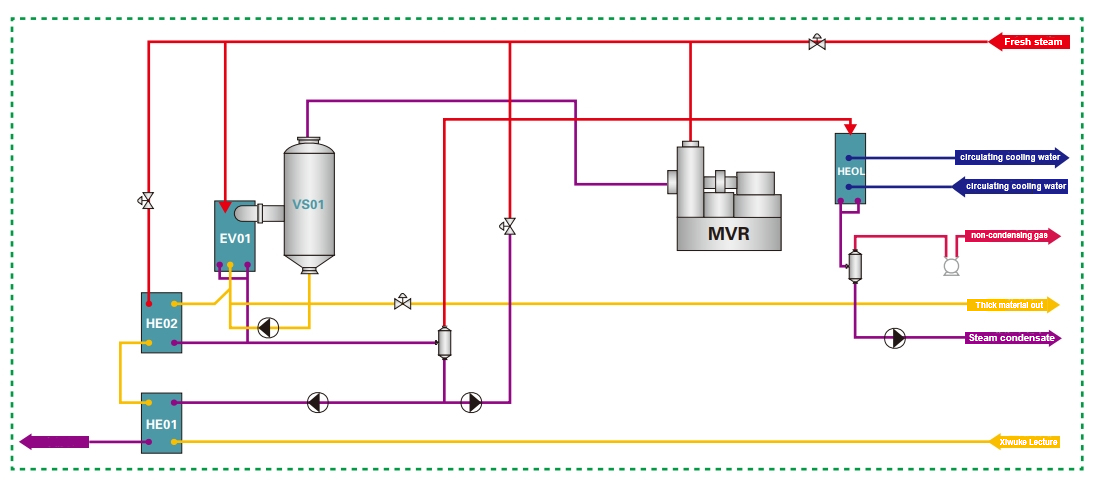

Process and equipment flow

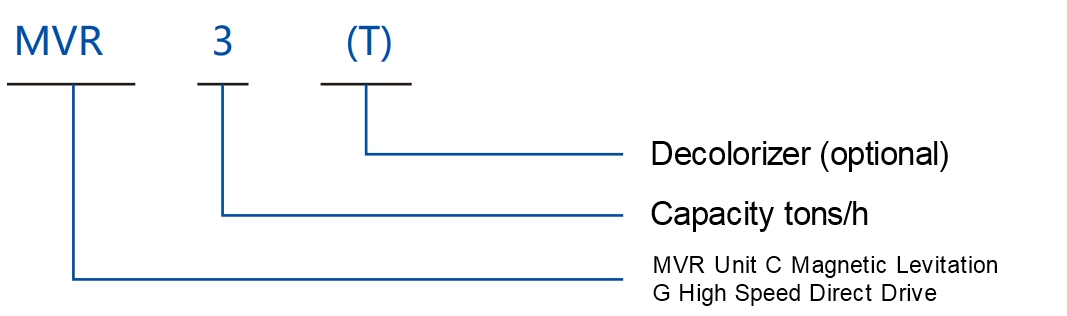

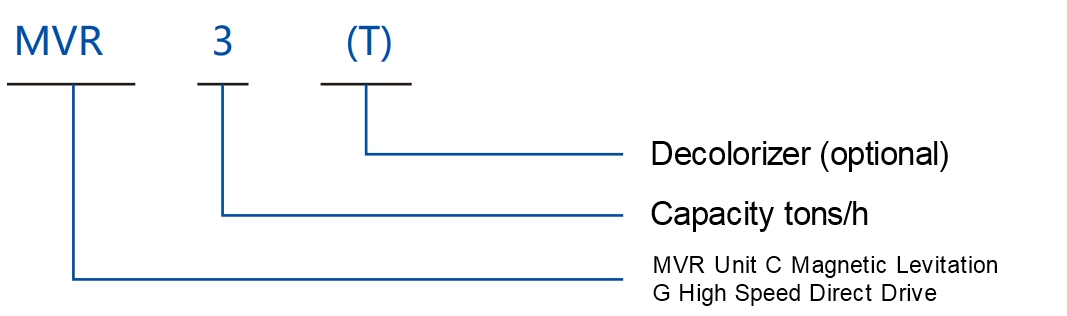

Product Model Description

Areas Of Application

鲁公网安备37100202000865号

鲁公网安备37100202000865号