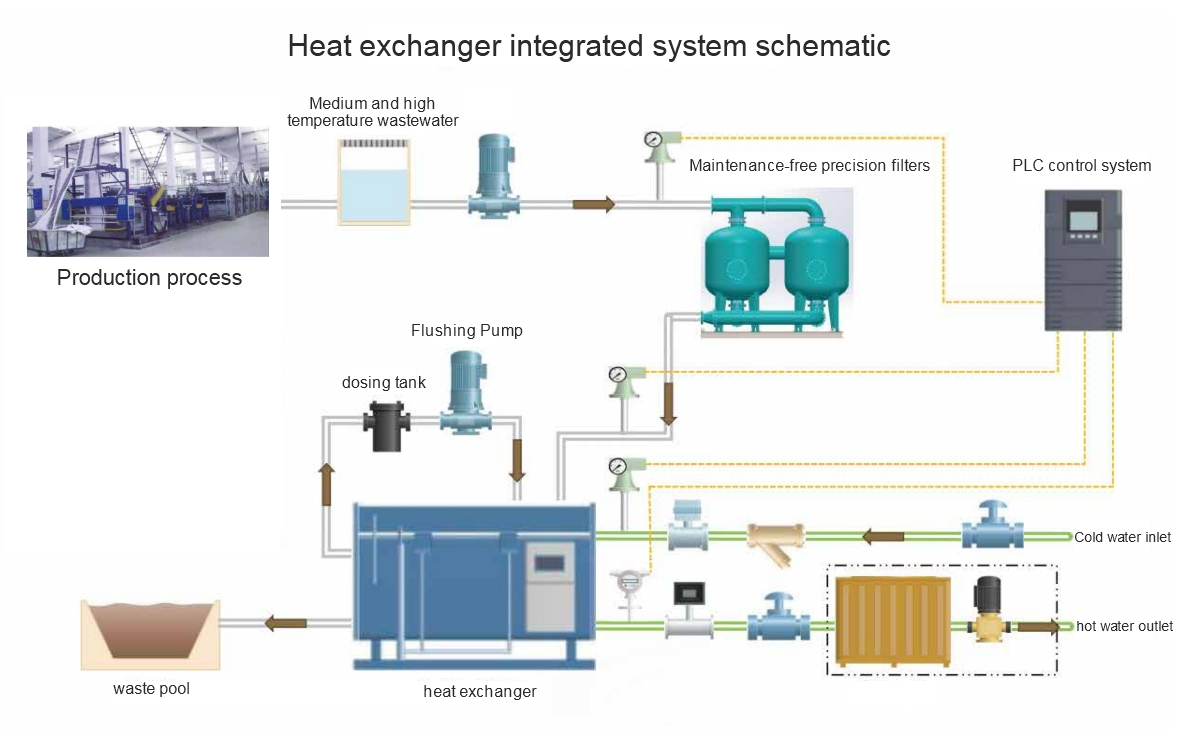

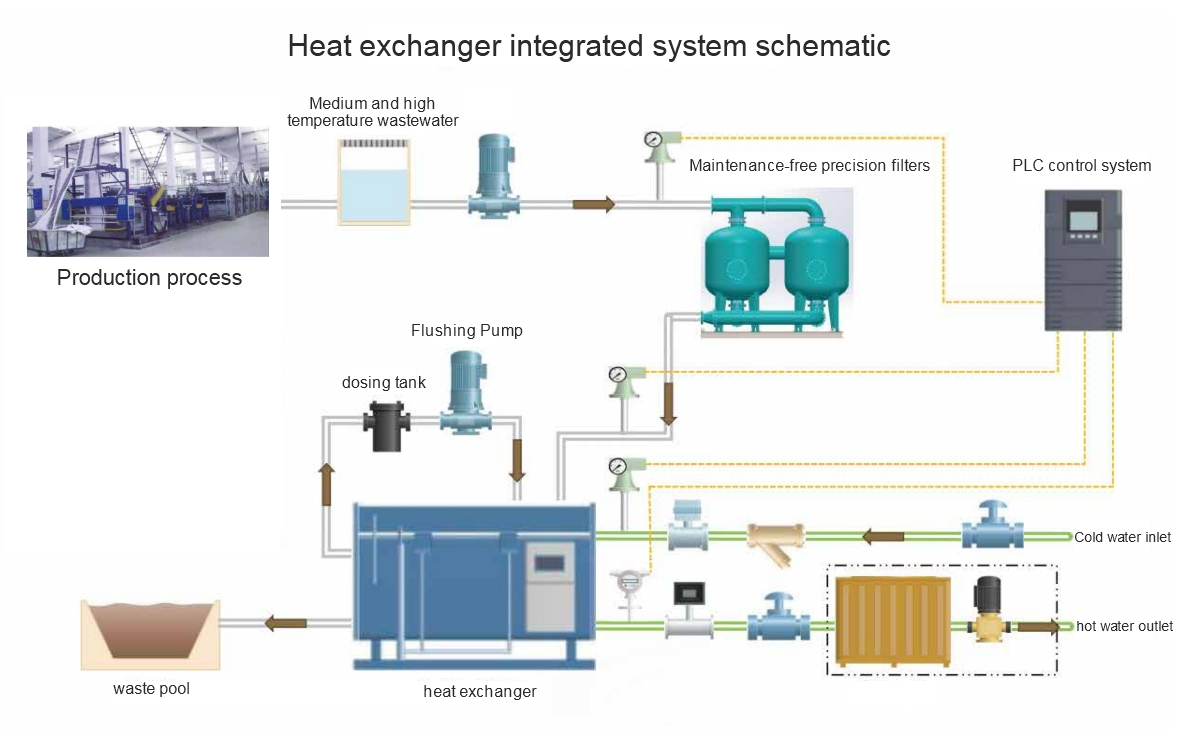

Working Principle

The waste heat recovery type integrated heat exchange unit is mainly composed of box (or machine room), heat exchange unit, dosing backwashing system, pipeline, valve and control system. It is arranged in a closed box (or machine room) after optimization design. It has the advantages of sophisticated hardware configuration, reasonable structural layout, advanced control system, convenient operation and management, and saving operating costs. It provides integrated heat exchange comprehensive solutions according to users with different needs. It is widely used in textile printing and dyeing, district heating, industrial waste heat recovery and other fields.

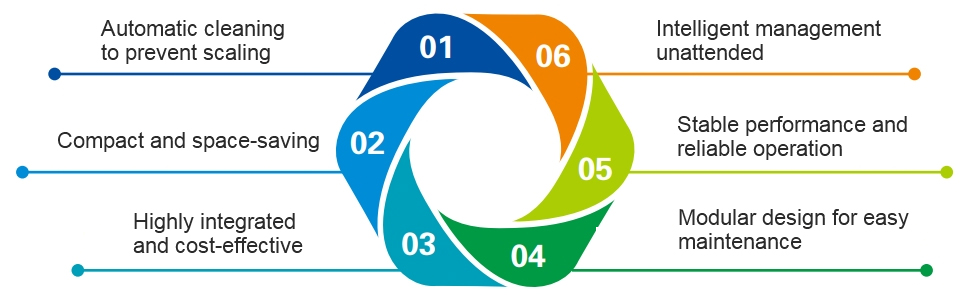

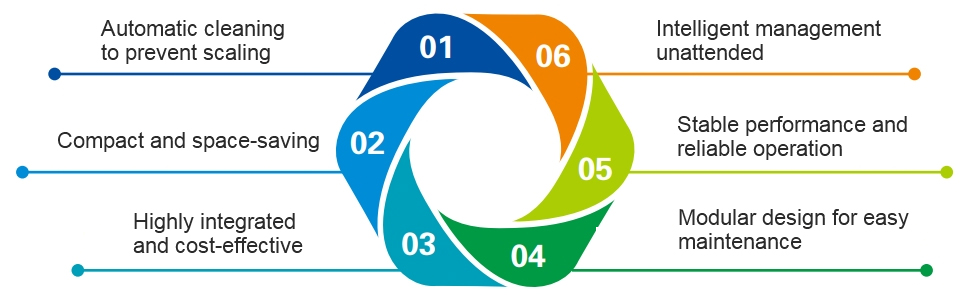

Automatic Cleaning

It is a patented product of our company, which can realize high-speed backwashing of sewage and clean water and high-speed backwashing of dosing without frequent disassembly and brushing. It can prevent scaling, blockage and scouring of the plate flow channel, extend the shutdown and maintenance period of the unitandimprove the working efficiency and heat exchange efficiencyof the unit to achieve full energy saving.

Easy to disassemble

Modular combination enables quick disassembly and combination of the integrated heat exchange unit.The plate and gasket of the plate heat exchanger are of anti-slip and anti-misalignment design wheninserting into the positions. Theadvantages are high efficiency, reliability and convenient disassembly.

High cost performance

Heat transfer efficiency is more than 5 times of the shell-and-tube heat exchanger with only 1/3 space occupation. Integrated structural design enables convenient on-site operation or movement which reduces installation and labor costs.

High Integration

It integrates the design of thermal machinery, process instruments, network communications, electrical control, etc. and optimizes the hardware and software design of the integrated heat exchange unit according to different user requirements to achieve unattended intelligent management.

Product Features

Technical Parameters

|

Serial number

|

Heat exchange water volume

(T/hour)

|

Heat exchange water volume

(T/day)

|

Wastewater heat ①

(kw)

|

Recovered heat②

(kw)

|

Steam Savings

(ton/hour)

|

Cost savings ③

(Yuan/hour)

|

Cost savings③

(Yuan/day)

|

Outline reference size ④

(L*W*H,mm)

|

|

1

|

15

|

360

|

436.1

|

392.5

|

0.6

|

112.6

|

2703.1

|

1000*900*1850

|

|

2

|

25

|

600

|

726.9

|

654.2

|

0.9

|

187.7

|

4505.2

|

1000*900*1850

|

|

3

|

40

|

960

|

1163.0

|

1046.7

|

1.5

|

300.3

|

7208.3

|

1600*1400*1850

|

|

4

|

60

|

1440

|

1744.5

|

1570.1

|

2.3

|

450.5

|

10812.4

|

1600*1400*1850

|

|

5

|

80

|

1920

|

2326.0

|

2093.4

|

3.0

|

600.7

|

14416.5

|

1600*1400*1850

|

|

6

|

100

|

2400

|

2907.5

|

2616.8

|

3.8

|

750.9

|

18020.7

|

1600*1400*1850

|

|

7

|

150

|

3600

|

4361.3

|

3925.1

|

5.6

|

1126.3

|

27031.0

|

2800*1800*2000

|

|

8

|

200

|

4800

|

5815.0

|

5233.5

|

7.5

|

1501.7

|

36041.3

|

2800*1800*2000

|

|

9

|

250

|

6000

|

7268.8

|

6541.90

|

9.4

|

1877.2

|

45051.6

|

3000*1800*2000

|

|

10

|

300

|

7200

|

8722.5

|

7850.3

|

11.3

|

2252.6

|

54062.0

|

3000*1800*2000

|

|

11

|

350

|

8400

|

10176.3

|

9158.6

|

13.1

|

2628.0

|

63072.3

|

3500*2100*2200

|

|

12

|

400

|

9600

|

11630.0

|

10467.0

|

15.0

|

3003.4

|

72082.6

|

3500*2100*2200

|

Note:

①The heat of wastewater is the heat released per unit time when the initial temperature of wastewater cooled downfrom 60 ℃ to 35 ℃.

②The recovery heat is recycled according to 90% of the temperature difference heat of wastewater.

③The cost savings are calculated based on the steam unit price of 200 yuan/ton.

④The overall dimensions are for reference only. Actual dimensions arebased on different working and service conditions.

⑤The calorific value of 1 ton steam is estimated at 600,000 kcal, which is 697KWH.

⑥When the ratio of waste water volume to new water volume is 1:1, the temperature of the new water can reach up to 53 ℃ from initial temperature of 30 ℃ after heat recovery.

Performance Comparison

|

Typology

|

photograph

|

clarification

|

Comparative Advantages

|

|

Shuanghe integrated heat exchanger

|

|

Maintenance-free filters

+ Heat exchange integration

+ backwash dosing function

|

+ Compact design

+ Cost-effective

+ High heat transfer coefficient

+ No fouling

+ Low differential heat transfer

+ Maintenance-free

+ Outdoor installation possible

|

|

Plate heat exchanger

|

|

General filtration

(Periodic cleaning)

+ Plate heat exchanger

(Frequent disassembly)

|

+ Compact design

+ Cost-effective

+ High heat transfer coefficient

+ No fouling

+ Low differential heat transfer

+ Maintenance-free

+ Outdoor installation possible

|

|

Shell and tube heat exchanger systems

|

|

General filtration

(Periodic cleaning)

+ Shell and tube heat exchanger

|

- Small heat transfer coefficient

- Large dimensions

- Heavy mass

- Easy to scale

- Frequent cleaning

- High investment

|

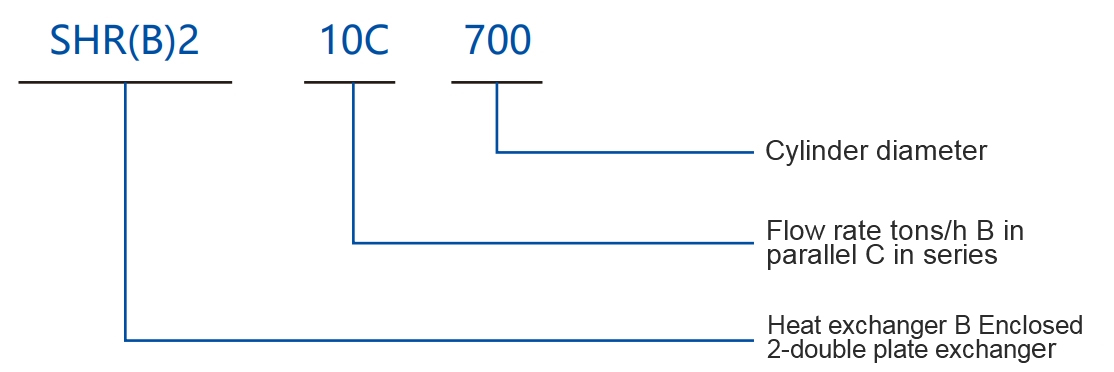

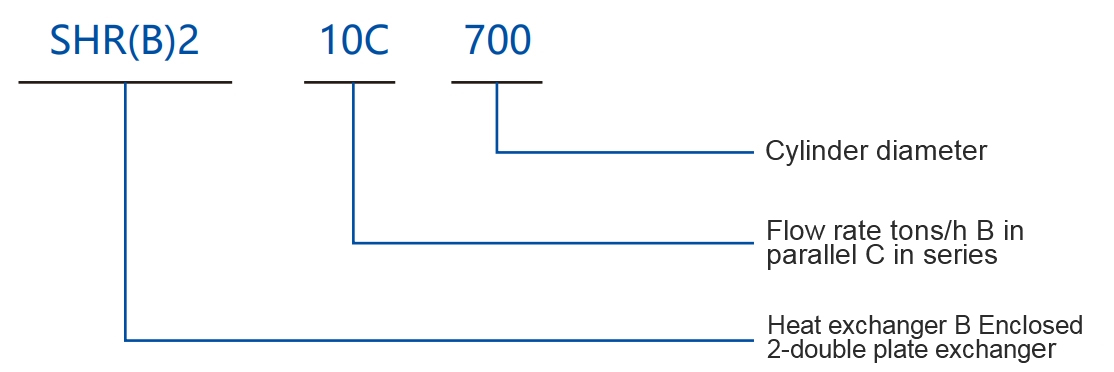

Product Model Description

System Process

Areas Of Application

鲁公网安备37100202000865号

鲁公网安备37100202000865号