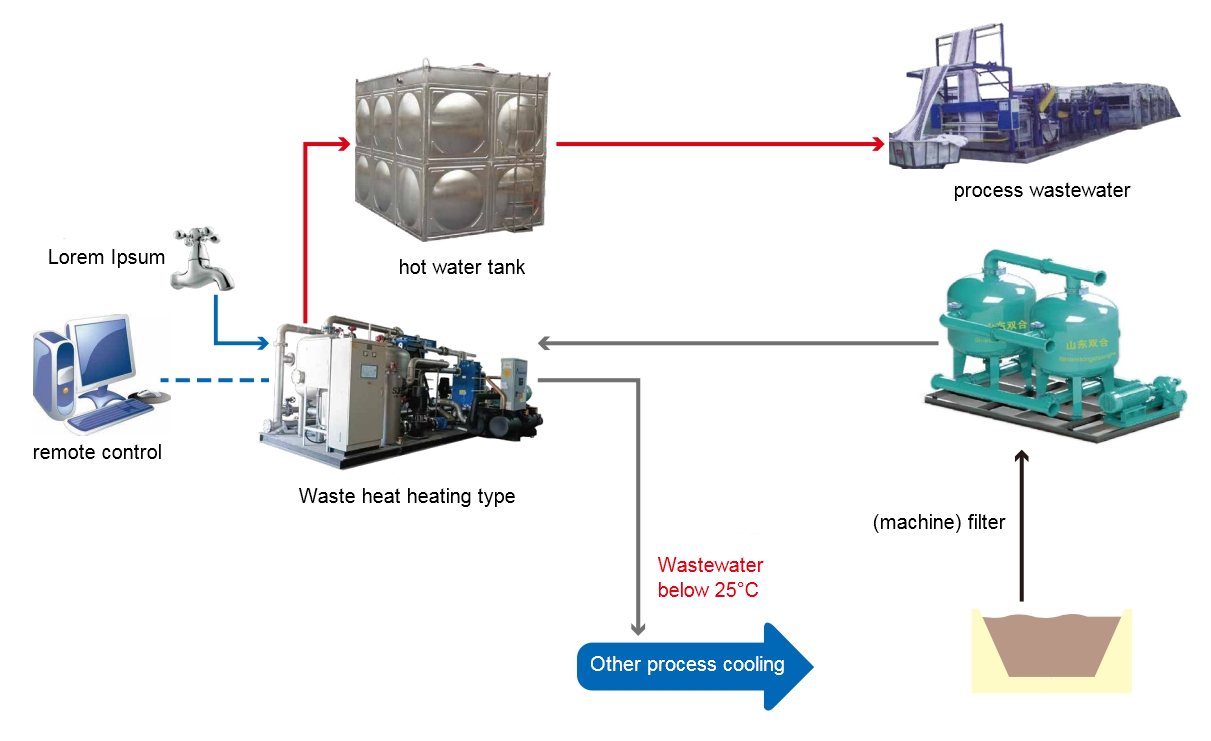

Working Principle

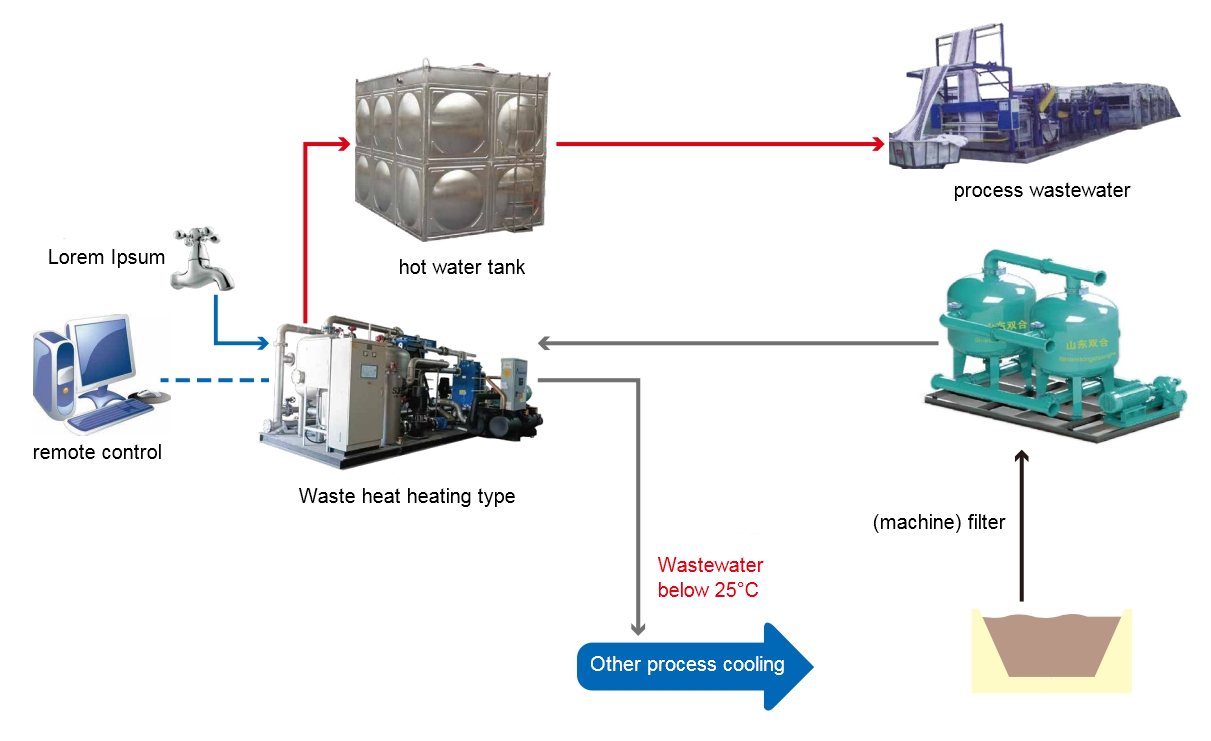

The heating type integrated heat exchange unit adopts stepped heat transfer and heat pump integration technology. Heat pump technology is an energy utilization method to efficiently recover medium and high grade waste heat by consuming a small amount of electric energy, which can extract more than 75% of the waste heat energy in the process wastewater. In addition, the cooling capacity discharged by the unit can also be used for the cooling process of the production workshop and the cooling process, and meet the process requirements that the temperature of the sewage mixed into the sewage treatment plant not higher than 38℃.

The waste water pump delivers the treated wastewater to the pre - and post-effect heat recovery heat exchanger, transfers most of the heat to the new water, and then releases the heat to the heat pump through the intermediate medium to cool the heat twice, and the final drainage temperature can be reduced to 20-25℃. At the same time, the released heat is absorbed by the refrigerant, then by the heat pump, the refrigerant transfers the heat to the new water through the intermediate medium, and the final temperature of the new water can reach up to 60-75℃.

The unit has a refrigeration function. The cooling output can be achieved by switching the function keys. When necessary, it can be directly connected to the cooling system for heat exchange, to cool down the cooling needed process or to improve the working environment of the workshop. The wastewater discharge temperature will increase, while hot water production is not affected.

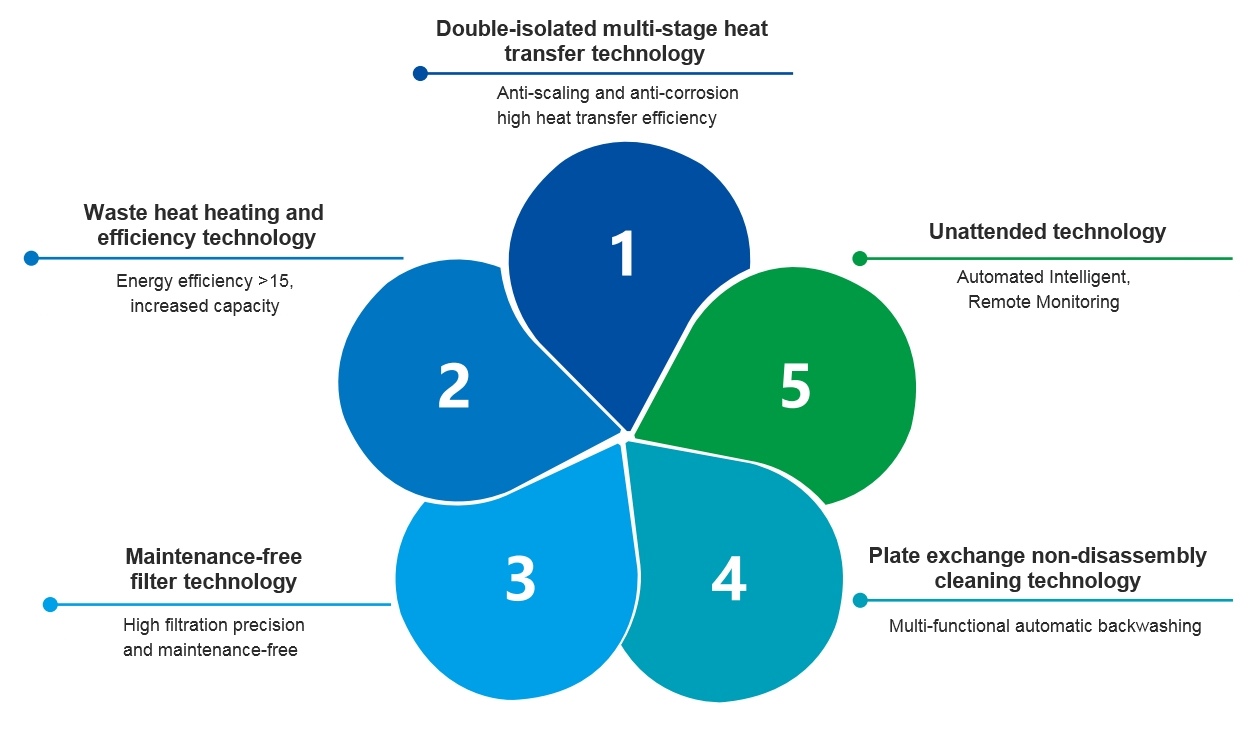

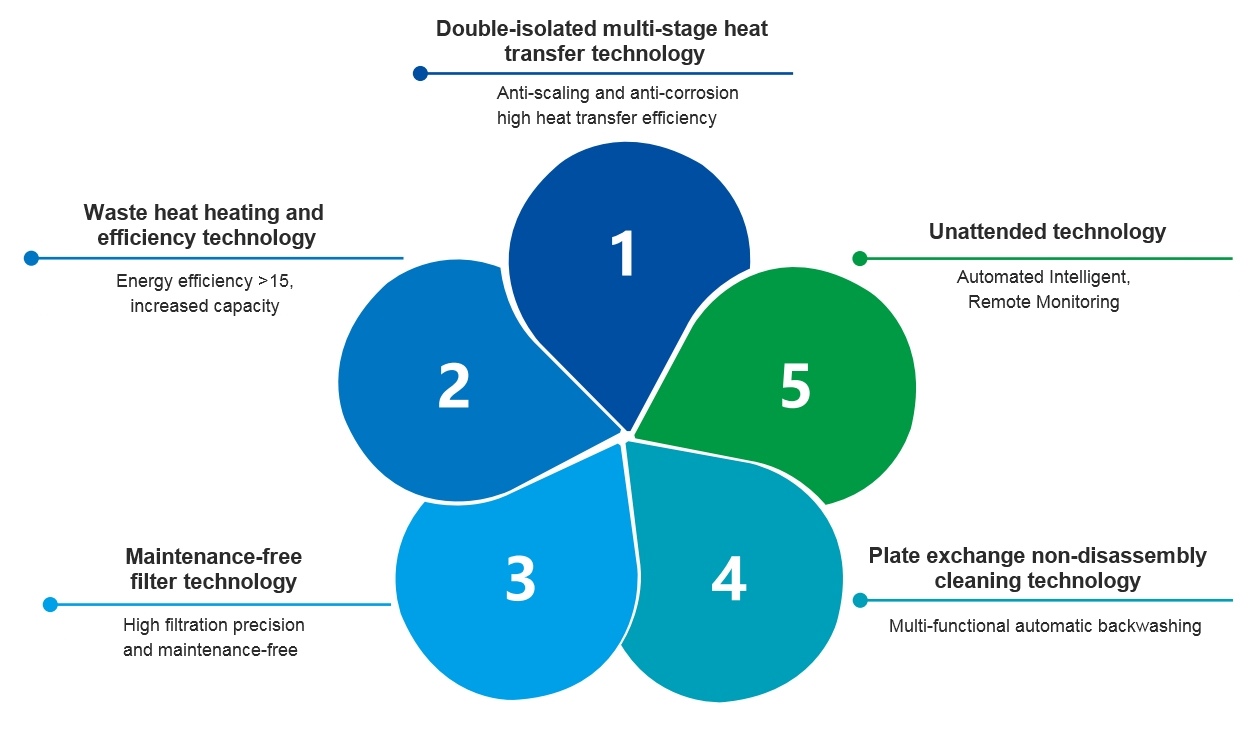

Product Features

Unit Parameters

|

serial number

|

Heat exchange water volume

(T/hour)

|

Heating water volume

(T/day)

|

Wastewater temperature

(°C)

|

Hot water inlet temperature

(°C)

|

Hot water outlet temperature

(°C)

|

Rated heating capacity

(KW)

|

System Energy Efficiency

|

Outline reference size

(L*W*H,mm)

|

|

1

|

8.5

|

200

|

50-80

|

7-30

|

60-75

|

523.9315

|

14-18

|

1000*900*1850

|

|

2

|

15

|

360

|

50-80

|

7-30

|

60-75

|

924.585

|

14-18

|

1000*900*1850

|

|

3

|

25

|

600

|

50-80

|

7-30

|

60-75

|

1540.975

|

14-18

|

1000*900*1850

|

|

4

|

40

|

960

|

50-80

|

7-30

|

60-75

|

2465.56

|

14-18

|

1600*1400*1850

|

|

5

|

60

|

1440

|

50-80

|

7-30

|

60-75

|

3698.34

|

14-18

|

1600*1400*1850

|

|

6

|

80

|

1920

|

50-80

|

7-30

|

60-75

|

4931.12

|

14-18

|

1600*1400*1850

|

|

7

|

100

|

2400

|

50-80

|

7-30

|

60-75

|

6163.9

|

14-18

|

1600*1400*1850

|

|

8

|

150

|

3600

|

50-80

|

7-30

|

60-75

|

9245.85

|

14-18

|

2800*1800*2000

|

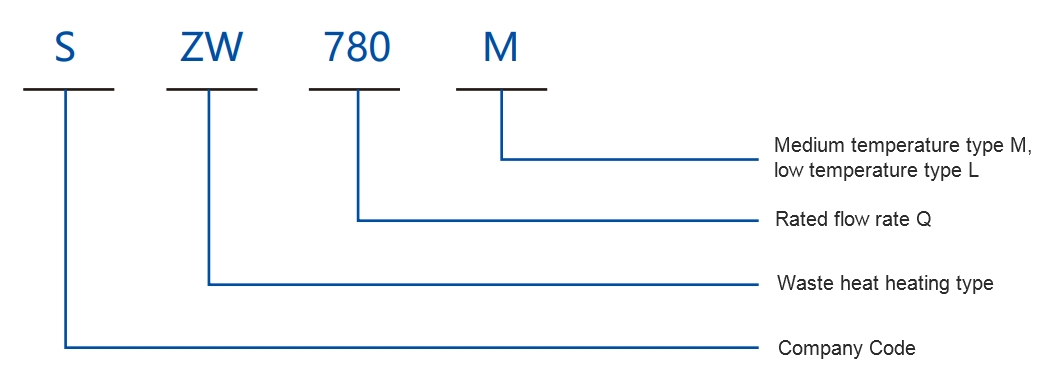

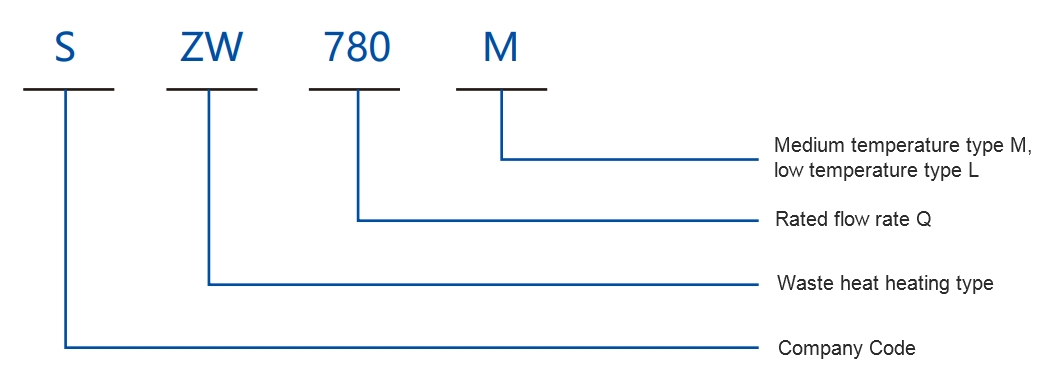

Product Model Description

Energy Saving Comparison

|

sports event

|

gas boiler

|

steam heat transfer

|

oil boiler

|

coal burning boiler

|

Compound heat power conversion

Heat exchanger

|

|

Type of energy

|

petroleum

|

vapor

|

diesel fuel

|

standard coal

|

Wastewater + Electricity

|

|

environmental

|

exhaust gas pollution

|

non-polluting

|

exhaust gas pollution

|

Waste residue, exhaust gas pollution

|

eco-friendly

|

|

safety

|

There are air leaks,

fire, explosion

etc. safety hazards

|

There is leakage,

Electric heat, tube aging

and other safety hazards

|

There is an oil spill,

fire, explosion

etc. safety hazards

|

There is poisoning,

fire, explosion

etc. safety hazards

|

Safe and reliable

Long life

|

|

convenience

|

professionally managed

|

professionally managed

|

professionally managed

|

professionally managed

|

unattended

|

|

Unit price of energy

|

3.2 yuan/m³

|

0.16yuan/kg

|

7.4yuan/kg

|

Restricted use

|

1yuan/kw·h

|

|

efficiency

|

0.9

|

0.9

|

0.9

|

16.8

|

|

Daily running costs

(yuan/day)

Based on 200 tons per day

water calculation

|

5149

|

4256

|

10792

|

613

|

|

Production of 1 ton

Hot water cost

(yuan/ton)

|

25.75

|

21.28

|

53.96

|

3.06

|

|

Production of 1kw

Heat cost

(Yuan/kw)

|

35.74

|

23.08

|

49.49

|

7.50

|

Note: 1. The rated heating operating parameters of the medium-temperature unit are counting base of 200 tons of 75°C hot water production per day.

2.The energy unit prices in the table are average values for a certain region.

System Process

Areas Of Application

鲁公网安备37100202000865号

鲁公网安备37100202000865号