Working Principle

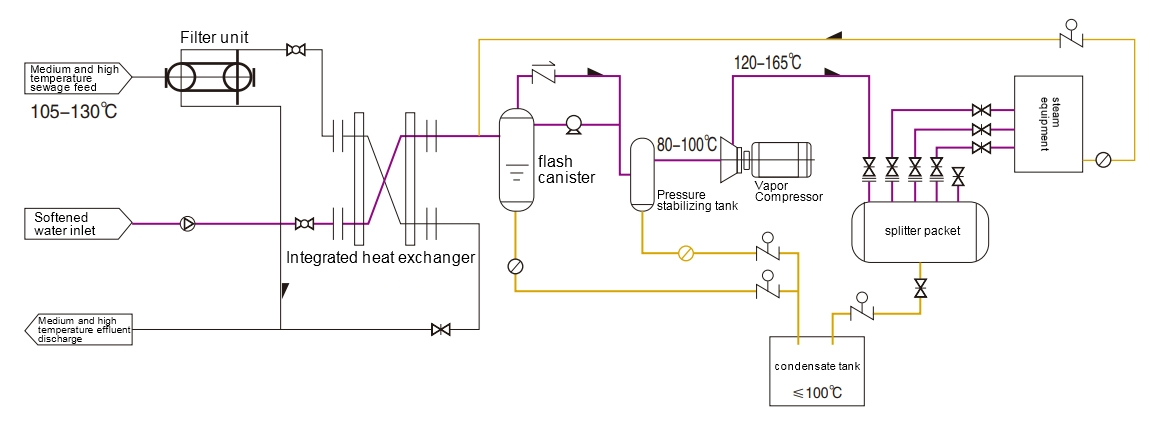

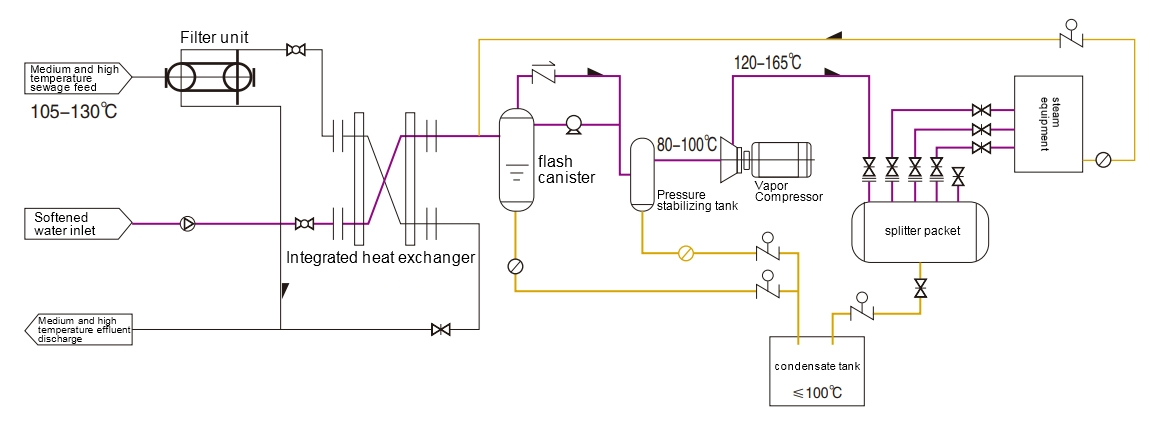

The low-grade waste heat (condensate water, wastewater) to steam unit uses a large amount of filtered industrial high-temperature wastewater above 95°C to transfer most of the heat of the wastewater to softened water (new water) and steam condensed water. Through the flash tank, the high-temperature softened water flashes into low-pressure saturated steam of 80°C to 95°C, which is boosted and heated by the steam compressor to generate and recycle the high-temperature steam of 130°C to 165°C. High-temperature steam is incorporated into the steam pipe network through the steam-separating drum for the production process. The entire process is intelligently controlled by PLC.

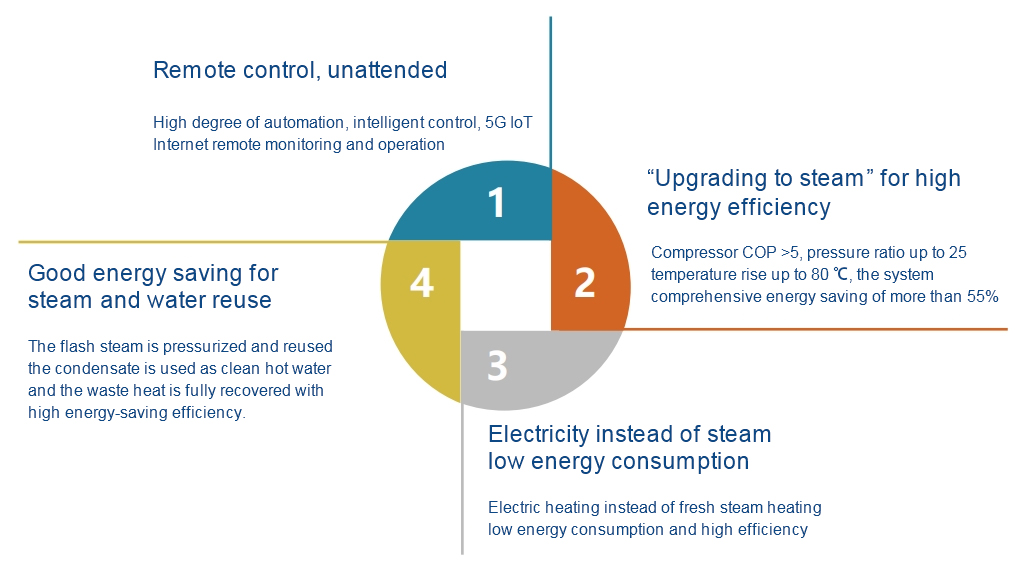

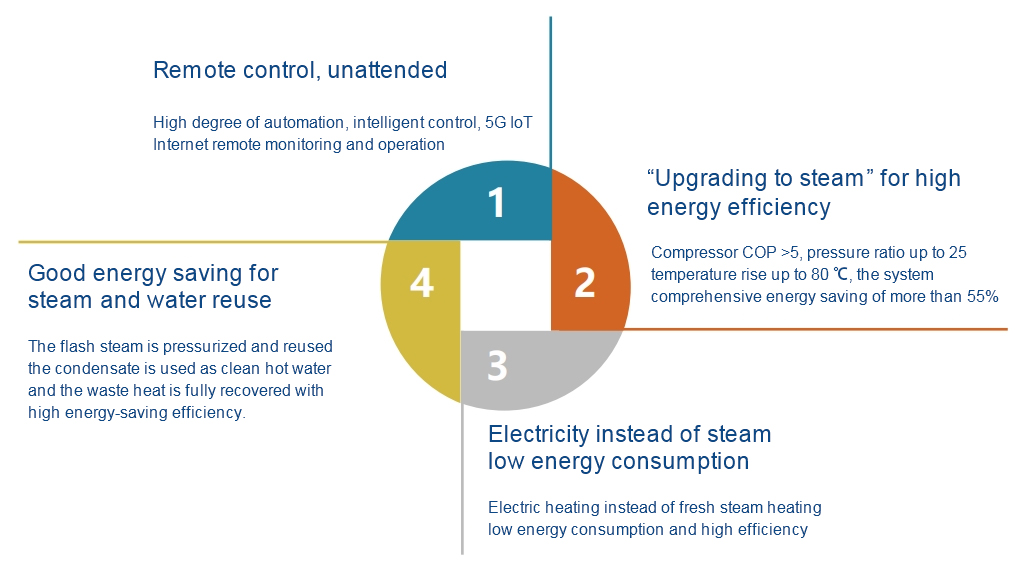

Product Features

Unit Parameters

|

Unit Model

|

Medium and high temperature wastewater temperature ℃

|

Conversion Steam Temperature

|

Suction temperature ℃

|

Electricity consumption of tons of steam kw.h/ton

|

Steam quality tons

|

|

GFZQ-1200

|

≥95℃

|

120℃-165℃

|

80℃-95℃

|

140-160

|

0.5

|

|

GFZQ-2400

|

≥95℃

|

120℃-165℃

|

80℃-95℃

|

140-160

|

1

|

|

GFZQ-3360

|

≥95℃

|

120℃-165℃

|

80℃-95℃

|

140-160

|

1.5

|

|

GFZQ-6720

|

≥95℃

|

120℃-165℃

|

80℃-95℃

|

140-160

|

2

|

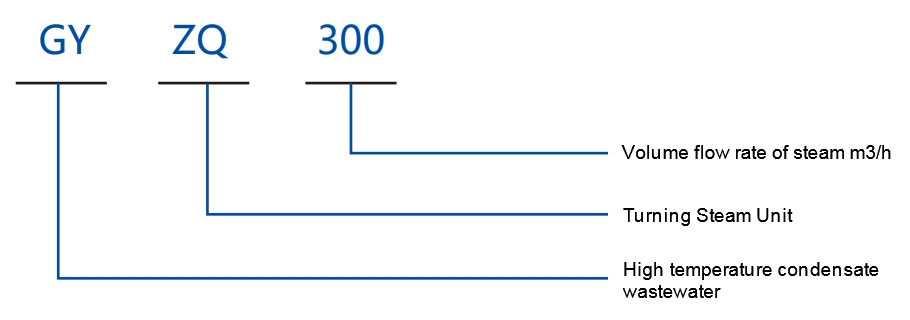

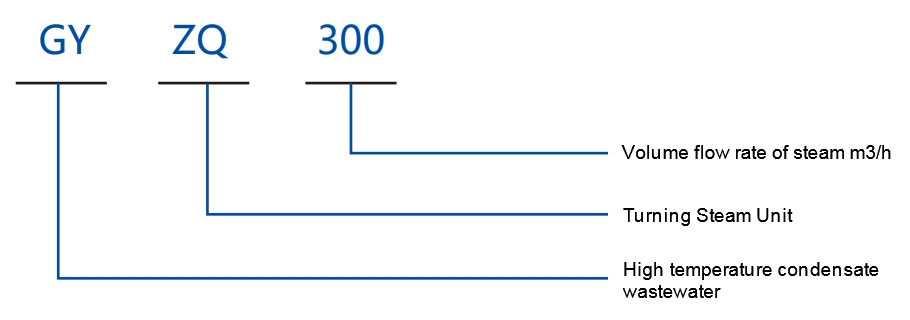

Product Model Description

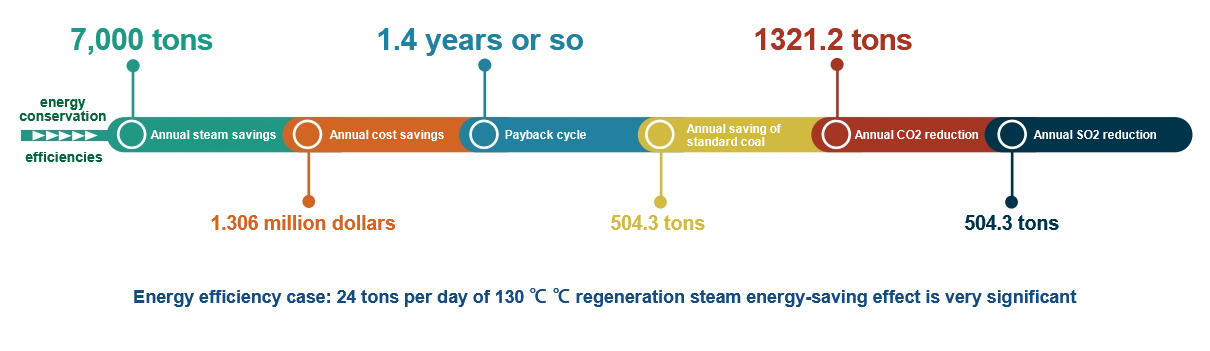

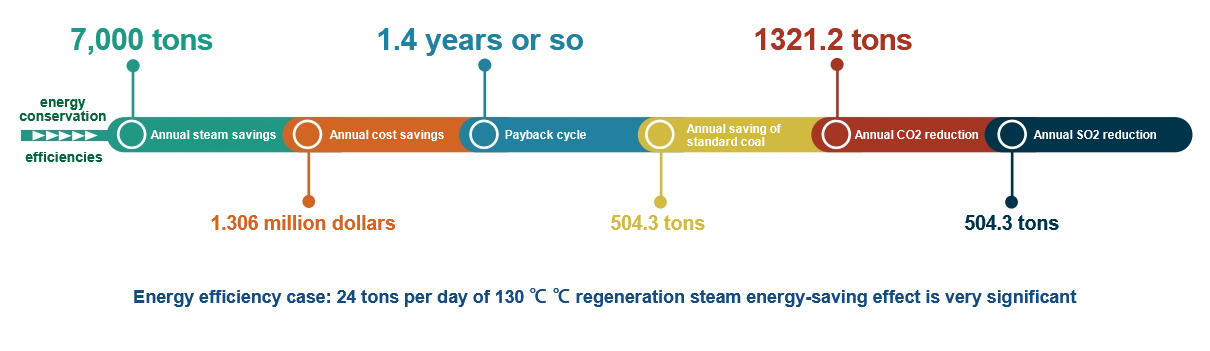

Energy Efficiency Gains

system process

Areas Of Application

鲁公网安备37100202000865号

鲁公网安备37100202000865号